The physics of growth

Growth is onw of my key areas of interest. The physics of growth comprises the mechanisms by which building blocks come together to form large scale structures in a way that is mainly dominated by local interactions and external fields. This is at the heart of how materials are made, from primordial grains to semiconductor manufacturing, but also extends beyond materials. The role that these interactions have on determining the resulting structure is something that I have always found fascinating.

Growth under the influence of chemistry

One of the fundamental questions is to understand how growth conditions affect the microstructure of the materials that it is being formed. This is particularly interesting at low temperatures, where the mobility of atoms is hindered, potentially preventing them to relax and form highly crystalline materials. Under these conditions, the details of the processes taking place at the surface can strongly impact the resulting microstructure, in some cases leading to highly ordered structures and crystalline materials.

Developing the ability to predict how growth conditions lead to a certain microstructure will accelerate the pace at which we can transfer processes and materials from lab to industry. And this is something that cuts across many applications, from semiconductor chip manufacturing to energy storage and quantum computing. It can also help us chart new paths towards the synthesis of new materials.

Combining experiments, models, and machine learning

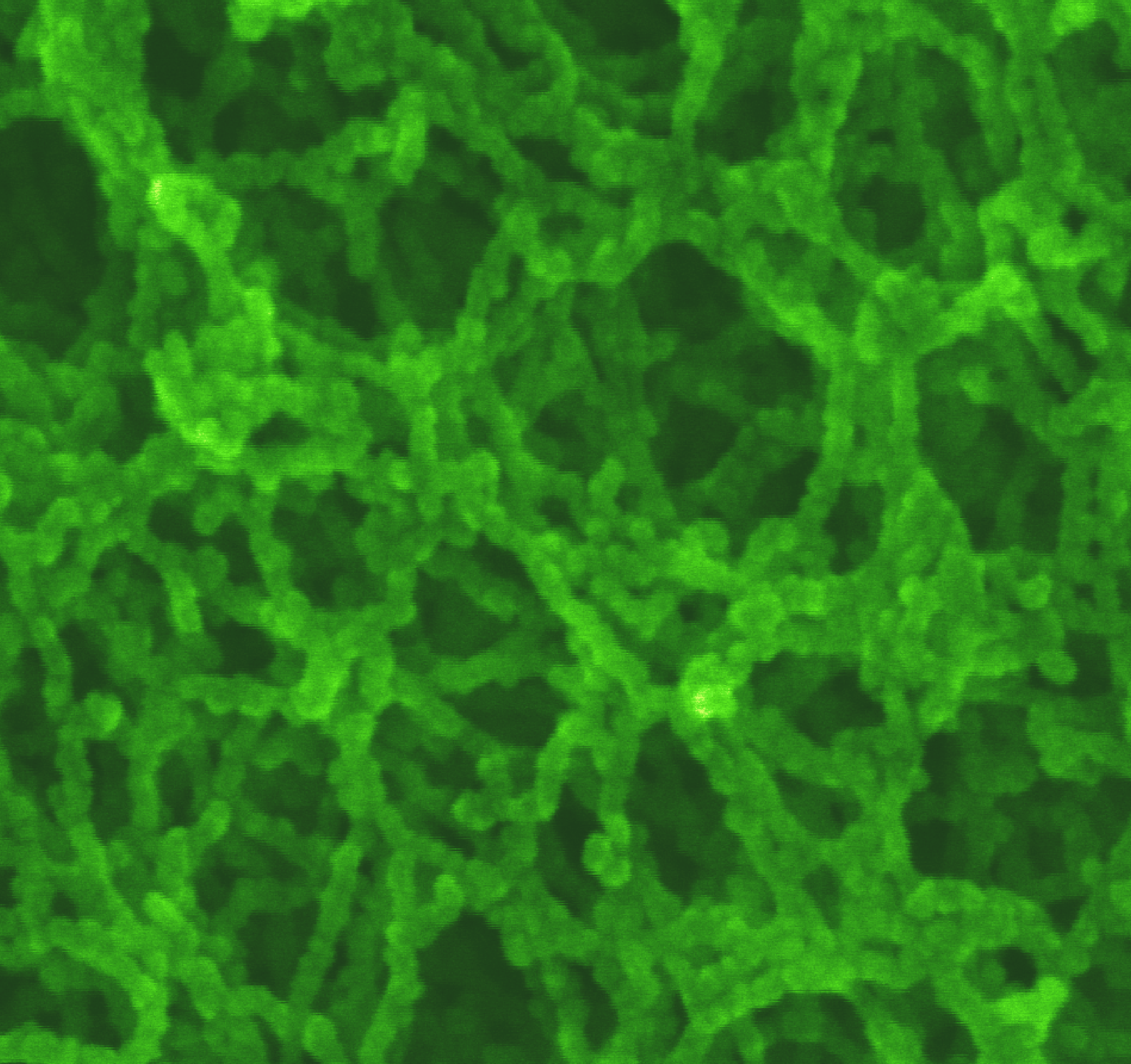

My approach to these questions is to combine experiments, simulations, and machine learning to deepen our understanding of the fundamental aspects of thin film growth and develop new applications. From a experimental point of view, we focus primarily on a technique called atomic layer deposition, which has the advantage of being extremely reproducible -when done right. We also leverage synchrotron radiation and other in-situ techniques to probe in detail the structure of the material as they evolve from its individual atoms.

From a simulation perspective, our focus in mainly on kinetic Monte Carlo simulations to model growth on arbitrary graphs, as well as the development of novel simulation tools to model reactive transport and predict growth within high surface area materials. These allow us to translate our fundamental understanding to wafer and feature length scales that are relevant for advanced manufacturing applications.

What role can machine learning and AI play in all of this? One example is the use of self-driving tools to explore and optimize new processes without a human in the loop, to surrogate models that can sidestep the need of doing complex simulations and directly use the data that we get from inline metrology and characterization tools to predict how to improve the way we make the materials. How many of these tools will become staples in our labs remains to be seen, but it is one of the questions of our times.

A historical note

We tend to see materials and chemistry as something that belongs in the lab, but developing the ability to make stuff has played a critical role in human history, and who can manufacture what at which cost and from which raw materials goes a long way in explaining our present. For a long time, this knowledge was largely empirical and completely independent from science. In fact, our ability to synthesize materials predates science by tens of thousands of years. Since the first half of the 20th century, though, they are strongly intertwined.

And beyond

Outside my day job as a researcher, there are many rabbit holes where my curiousity goes regarding growth: the physics of self-assembly, the early stages of the solar system, the raw materials used in manufacturing, or the process of morphogenesis in biological systems are areas that I find fascinating. There is also beauty in growth, from the shapes of crystals and the landscapes sculpted by erosion, to the underlying models that help us connect the morphologies observed in vastly different systems.